What Factors Influence The Laser Marking Machine Price In India?

As industries across India adopt modern manufacturing practices, laser marking machines are becoming essential for businesses that require precision, durability, and speed. Whether you run a small fabrication shop or manage operations at a large OEM, one question comes up often: What affects the laser marking machine price? While pricing varies based on several factors, understanding what drives the cost helps you make a more informed and confident investment. This guide breaks down those factors from an Indian perspective, so you can focus on getting the best value for your business.

Here Are The Factors That Influence The Laser Marking Machine Price In India

Type of laser source

The type of laser source plays a significant role in determining cost. The most commonly used types are:

Fiber Laser – Best suited for marking metals like stainless steel, brass, and aluminum. These are preferred across Indian industries due to their durability and low maintenance.

CO₂ Laser – Ideal for organic materials like acrylic, leather, wood, and plastic. These industries often use these in packaging, signage, and creative projects.

UV Laser – Used for marking plastics, glass, and heat-sensitive materials with excellent detail.

Each laser type has different use cases, and selecting the right one ensures optimal performance for your material and application.

Laser power (wattage)

Laser power, measured in watts, directly impacts marking speed and depth. In India, most manufacturers offer machines in a range of wattages, such as:

Low Power (e.g., 20W) – Suitable for basic engraving and low-volume jobs.

Medium Power (e.g., 30W–50W) – Ideal for faster production and deeper marks.

High Power (e.g., 100W and above) – Best for heavy-duty industrial usage.

Higher-wattage machines are typically used by manufacturers handling large volumes of hard materials. Selecting the correct wattage ensures your process is efficient and scalable.

Marking area size

The marking area (or working field size) defines the surface the laser can cover in one pass. Smaller machines are ideal for compact items such as tools, labels, or tags. Larger working areas are preferred for panels, sheets, or marking multiple parts simultaneously.

If your operations involve batch processing or varied product sizes, a larger marking bed offers flexibility and improves throughput, although it may require a higher initial investment. It also reduces the need for frequent repositioning or manual adjustments, which can save time and lower the risk of human error. For job shops and custom fabrication units, this added capability supports faster turnaround and more efficient project handling.

Machine build quality

The quality of materials and components used in the machine directly influences both longevity and performance. Key aspects include:

Strong, vibration-free metal frames

Industrial-grade internal wiring

Sealed optical paths

Proper cooling and dust-protection systems

Machines with higher structural integrity can handle demanding workshop conditions and deliver consistent results over time. This is especially important for manufacturers running multiple shifts or high daily volumes. Additionally, better build quality reduces maintenance frequency, minimizes calibration drift, and ensures safety compliance, making it a critical factor for long-term reliability and operator confidence.

Software and control system

Modern laser marking machines come with user-friendly control software, often featuring:

Barcode/QR code generation

UID marking templates

Logo and image imports

Batch processing tools

Multi-language support

ERP integration

Advanced systems also offer cloud connectivity or data logging features for traceability. High-quality software reduces operator training time, improves efficiency, and minimizes marking errors, making it a wise long-term investment.

Automation options

Automation adds efficiency to repetitive marking tasks. In India, some of the most popular upgrades include:

Rotary attachments – For marking cylindrical parts like pipes, bottles, and tools.

Auto-focus laser heads – To dynamically adjust marking height for parts of varying sizes.

Vision systems – For camera-guided alignment and inspection.

Conveyor systems or XY tables – For continuous or large-batch production.

These features enhance productivity and reduce operator intervention, making them ideal for growing businesses or those looking to scale operations smoothly.

After-sales support and warranty

Service support is a crucial element when evaluating a machine's long-term value. A cheaper machine with poor service can lead to costly downtimes. In India, reputed manufacturers offer:

On-site installation and training

1–2 year warranties

Remote troubleshooting

Spare part availability

Annual maintenance contracts (AMCs)

Reliable after-sales service ensures your operations run smoothly and resolves any issues promptly, especially crucial in high-volume or deadline-driven environments. A dependable service network also provides regular health checks, firmware updates, and expert advice, helping you extend the machine's life and maximize uptime.

Customization and industry-specific needs

Depending on your sector, you may require a machine specifically designed for handling materials, meeting marking requirements, or adhering to compliance standards. For example:

Jewelry – Requires high-resolution detail and precise laser control.

Automotive – Needs deep engraving and batch traceability.

Medical – This may require micro-marking with traceability for instruments or implants.

Custom enclosures, multi-axis movement systems, or integration with existing assembly lines can add to the cost, but offer streamlined efficiency for specific industrial needs. In sectors with regulatory or export demands, these customizations help ensure compliance and quality control. They also support automation goals, reduce manual handling, and improve overall production accuracy, making them a worthwhile investment for specialized applications.

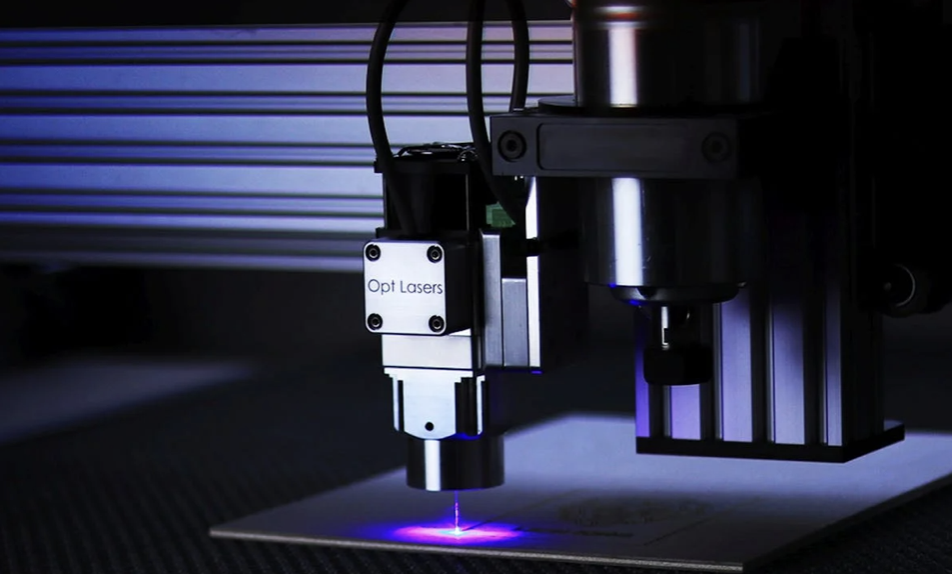

What Is A Laser Marking machine?

A laser marking machine utilizes a focused beam of light to mark or engrave materials permanently. It's widely used for:

Barcodes

QR codes

Serial numbers

Logos

UID marking

Batch and traceability codes

These machines are fast, contactless, and extremely precise, making them ideal for industries like automotive, aerospace, electronics, medical devices, FMCG packaging, and jewelry.

The Final Thoughts

When choosing a laser marking machine in India, it's not just about picking the most affordable model—it's about selecting a machine that aligns with your business's goals, workload, and expansion plans. The right machine will consistently deliver precise results, reduce manual labor, and integrate seamlessly into your production flow. Start by assessing what you'll be marking, how often, and what finish or durability is expected from the marks. Then, consider key technical requirements such as laser type, wattage, marking area, and software features. Ensure that you choose a brand that offers local support, technician availability, and quick-response service when needed.